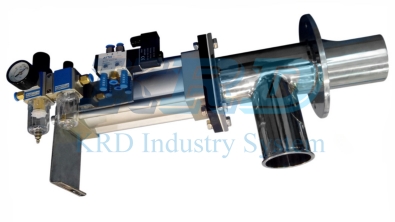

The fluidizer is an aiding component in the discharge process of bulk powder materials from silos.

Types

Fluidizers include silo fluidizers, disc fluidizers, and plate fluidizers, with the silo fluidizer being the primary type. It is installed at the bottom of the hopper, where air is introduced through a porous plate to fluidize the powder, enhancing its flowability and preventing bridging, ensuring smooth discharge.

Product Features

Integrates the effects of vibration and jet fluidization.

Works directly on the material without adversely affecting the silo.

- Low Humidity Sensitivity:

Generates intense high-frequency vibrations from air introduction, making it effective under various humidity conditions and suitable for diverse environments.

- Bridge and Arch Breaking:

Effectively disrupts issues like bridging, arching, rat-holing, adhesion, and accumulation, enhancing material flow.

Compressed air flows along the silo walls, reducing friction between the material and the walls, thus protecting the material.

Constructed from high-polymer silicone materials, ensuring a long service life.