The loading sleeve is a crucial device used in the fluid loading and unloading process across various industries, specifically for bulk materials in trains, tankers, trucks, and containers.

Basic Components

Feed Chute:

A simple feed device for material entry into the hopper.

Hopper Body:

Available in various designs; damped hoppers effectively reduce dust. The top cover connects to the central cylinder with a flexible joint, while the lower end features a conical discharge outlet.

Stopper:

Located within the hopper, it allows material to flow through the annular gap between it and the conical outlet.

Elastic Suspension Mechanism:

Suspends the hopper beneath a fixed support; when the material is discharged, it raises the hopper to seal the conical outlet.

Telescopic Dust Cover:

Encloses the hopper and extends into the vehicle, preventing dust and wind ingress.

Level Sensor:

Monitors loading status and automatically halts operation when full.

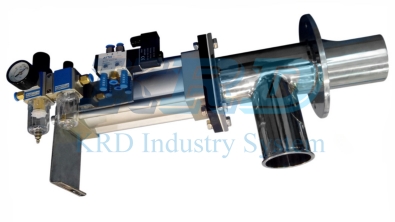

Control System:

Provides reliable operation, with options for automatic or manual control, ensuring safety features against inadvertent activation.

Working Principle:

During loading, the vehicle positions beneath the loading sleeve. A lift releases the wire rope, lowering the telescopic dust cover into the vehicle. Opening the discharge gate allows material to flow from the feed chute into the hopper, which descends to release the material through the conical outlet. The dust cover surrounds the material column, preventing dust emission and ensuring safe loading.

The telescopic dust cover's lower opening is equipped with a level sensor to automatically adjust its height based on loading levels, enabling automated control throughout the loading process.

Product Features

- Precision Rotating Joint:

Machined from CNC equipment, featuring a dual-roller support for enhanced load capacity and flexibility.

Uses enhanced PTFE materials for excellent sealing, wear resistance, and corrosion resistance.

The loading sleeve is balanced with a spring, allowing smooth manipulation across its working range.

Offers various materials and structural types tailored to different loading conditions and materials.

- High Throughput and Longevity:

Designed for efficient and durable performance, easy installation.

Can be interlocked with feeding facilities for automated loading and unloading processes.

Equipped with a fully automatic control system for simplified operation.

Maintains a closed environment during loading, minimizing dust pollution.

High filling rate (up to 96%) with fast loading times (5 to 15 minutes) and precision (0.2%).

Suitable for non-corrosive, low-abrasive bulk materials in industries like construction, power, metallurgy, coal, and chemicals.