Product Introduction

The pneumatic conveying system, also known as an air conveying system, is an eco-friendly technology that uses an air stream as a carrier medium to transport granular or powdery materials. Materials are suspended in air at a certain velocity and transported through pipelines to the discharge point, achieving the goal of material conveyance.

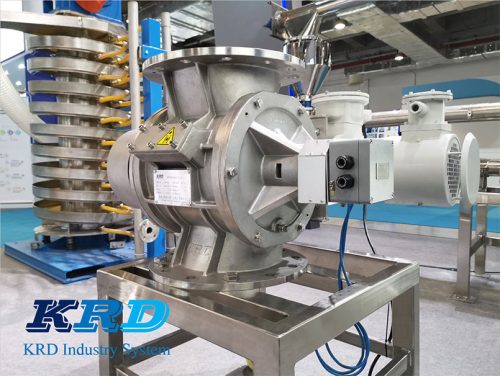

Product Structure

The pneumatic conveying system mainly consists of feeding equipment, conveying pipelines, material-gas separation equipment, air supply, and purification equipment.

Working Principle

The pneumatic conveying system can be divided into three types: positive pressure, negative pressure, and combined positive-negative pressure systems.

Positive Pressure Pneumatic Conveying System

When the starting point of the material is under positive pressure and the destination is under zero pressure, it is called positive pressure conveying. The general working pressure ranges from 0.1 to 0.5 MPa.

Negative Pressure Pneumatic Conveying System

When the starting point of the material is at zero pressure and the destination is under negative pressure, it is called negative pressure conveying. The general working pressure ranges from -0.04 to -0.08 MPa.

Pneumatic conveying can also be categorized based on the conveying form into dilute phase, dense phase, and medium phase:

- Dilute phase conveying: Solid-to-gas ratio 0~10; velocity 16~35 m/s.

- Medium phase conveying: Solid-to-gas ratio 8~20; velocity 12~20 m/s.

- Dense phase conveying: Solid-to-gas ratio 8~100; velocity 1~8 m/s.

Dense Phase Conveying:

Dense phase conveying is an energy-efficient method that uses extremely low speeds to smoothly transport abrasive or fragile materials through pipelines. It minimizes product degradation and reduces equipment wear. In this method, the airflow causes the material to clump together at the bottom of the pipeline, allowing air to flow through the porous material and achieve low-speed material conveyance. This method is particularly suitable for food, pet food, and chemicals.

Traditional methods use high-pressure compressed air in combination with pressure vessels to send materials into pipelines. However, continuous dense phase systems typically use low-pressure components like blowers and rotary valves. Although continuous dense phase systems are not commonly used due to unstable pressure and leakage issues, KRD's continuous dense phase system solves these problems. The KRD system can transport granular materials efficiently and smoothly. It controls the amount and speed of air passing through the pipeline, with precise pressure monitoring to manage airflow, compensate for pressure drops or temperature changes, and ensure a uniform air pressure suitable for conveying materials. This continuous dense phase system is optimized for efficiency by considering various factors during its calculations.

Dilute Phase Conveying:

Dilute phase pneumatic conveying uses air or other gases to suspend and transport material particles through a pipeline. It is particularly suitable for non-fragile and non-abrasive materials and can convey materials of various sizes, shapes, and densities. These systems are typically lower in investment cost and are often provided as components. However, some systems are oversized with inadequate performance.

KRD has developed the KRD Enhanced Dilute Phase Pneumatic Conveying Controller, which reduces blower speed to the minimum necessary, enhancing the performance of dilute phase pneumatic conveying. Typically, dilute phase systems need to account for the blower’s maximum operating conditions, such as the highest speed and longest distance, ensuring sufficient air is present in the pipeline.

The KRD controller can calculate based on system information such as pipeline size and conveying pressure, setting the blower to the ideal speed. The blower speed algorithm can be adjusted according to user-programmable specific conveying speeds. Optimized systems can reduce energy consumption by about 20% and also reduce material degradation and equipment wear.

KRD has achieved unprecedented energy savings in dilute phase conveying, showcasing the most efficient dilute phase pneumatic conveying technology, with energy savings of up to 30% compared to traditional methods. With blade compressor technology, it supplies oil-free air with maximum efficiency and reliability. Compared to traditional technology, energy efficiency can improve by 34%, ensuring optimal performance at different speeds.

Product Features of Pneumatic Conveying

Easy installation, low control costs, and short construction time. The main components are welded structures made of steel plates, consisting of pipes and tank-shaped components, with no relative movement between components, which reduces maintenance costs.

Fewer components require operation, and it requires fewer operators, increasing automation and reducing personnel costs.

- High Conveying Efficiency:

The conveying medium is air, which can be exhausted directly into the atmosphere at the terminal. During conveying, the feeding inlet can continuously add material, enabling continuous conveying.

Since materials move within pipes and are kept in a negative pressure environment, there is no leakage or dust, which protects the environment and the health of operators.

The pipeline can be set up according to site conditions, easily adapting to the factory layout, fully utilizing workshop space, and saving operational costs.

Common Materials Suitable for Pneumatic Conveying:

Many powder and granular materials can be conveyed pneumatically. The characteristics of each material affect the suitability and efficiency of the conveying system, so it is essential to test the material before selecting the system.

Examples of common materials suitable for pneumatic conveying

- Food Industry: Flour, soybean cake, seasoning powder, fish meal, wheat, cocoa, salt, grains, soybeans, dry yeast, cottonseed, cellulose, starch, granulated sugar, etc.

- Chemical Industry: Zinc oxide, hydrated lime, sodium carbonate, silica gel, sodium nitrate, aluminum hydroxide, sodium chlorate, sodium phosphate, sodium bicarbonate, borax (acid), gypsum powder, zinc powder, nickel powder, carbon black, iron oxide powder, polypropylene, PTA, PET, ABS, SBS, PVC, fly ash, nylon pellets, carbon, coke granules, cement, iron pellets, rubber granules, talc, dolomite, limestone, magnesium oxide, silica, titanium dioxide, kaolin, fluorite powder, bentonite, clay, bauxite, white clay, feldspar, Glauber’s salt, etc.

- Agriculture and Livestock Industry: Feed, fertilizers, urea granules, etc.

- Others: Wood chips, detergent powder, tobacco leaves, etc.