Vibrating conveying is a third form of bulk material transportation, distinct from traditional mechanical and pneumatic conveying. Materials rely on the conveying carrier, and under the influence of vibrational force, they are propelled forward in a parabolic motion, completing the transportation process.

Vibrating Conveyor Drive Types

1. Special vibrating motors

2. Electromagnetic exciters

Conveying Carrier Types

Trough or tube.

Equipment Configuration

Long-distance conveying (dual-body structure) and short-distance conveying (single-body structure), available in open or sealed designs.

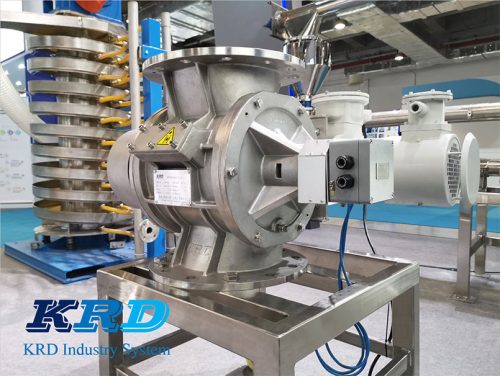

Components

Special vibrating motors, electromagnetic exciters, conveying tubes, conveying troughs, drive saddles, highly elastic and high vibration-isolation metal coil springs or rubber springs, leaf springs, structure body, controllers, flexible connections, and clamps.

Advantages of Vibrating Conveyor

1. Suitable for conveying various powder and granular materials such as plastic granules, flour, activated carbon, iron oxide, lithium salts, cobalt salts, etc. It is especially ideal for transporting fragile materials like potato chips, cereal flakes, tablets, and pills.

2. Single-body vibrating conveyors can achieve conveying distances of up to 7.2 meters, while dual-body vibrating conveyors can reach up to 30 meters.

3. Can be equipped with additional functions like heating, cooling, and drying, depending on material characteristics.

4. Low energy consumption, with minimal utility costs (vibrating motors are not subject to heavy power consumption regulations).

5. Can be designed with multiple inlet and outlet points, operates quietly, is reliable, stable, easy to operate, and has low maintenance costs.

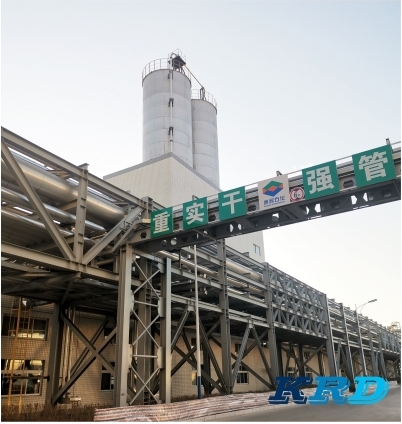

Main Applications

The vibrating conveyor is widely used in industries such as new energy (lithium batteries), food, chemicals, pharmaceuticals, and building materials.